News

News

15

2023

-

06

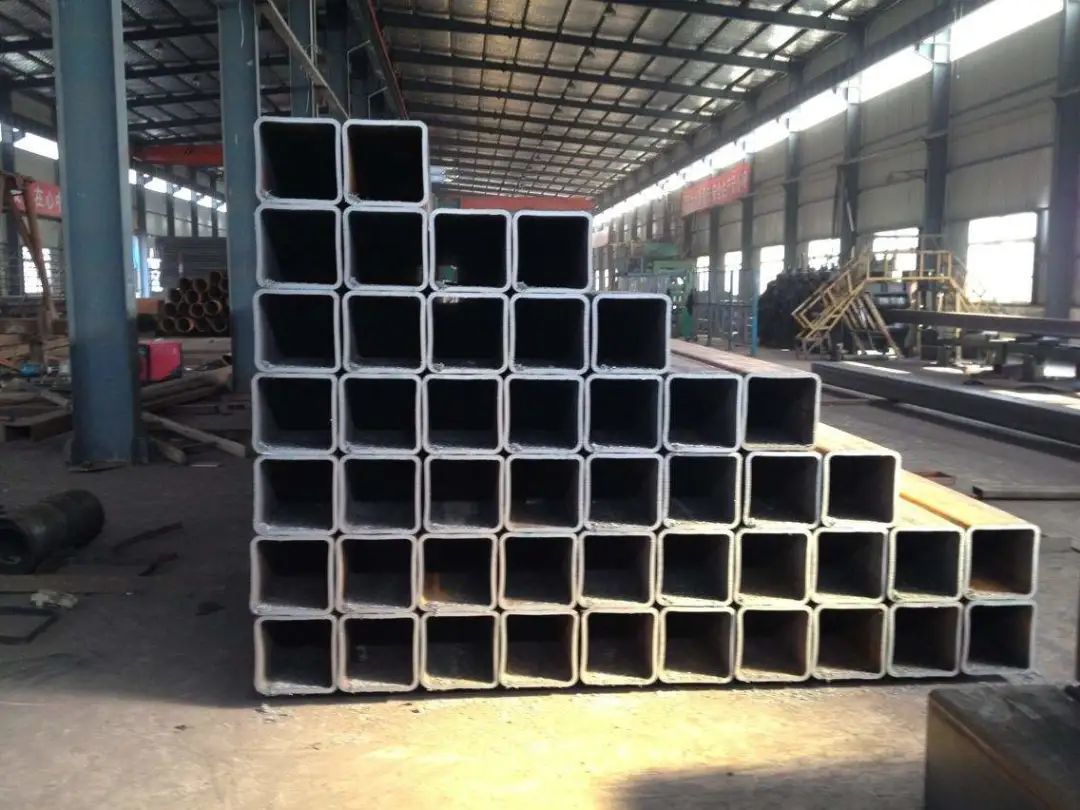

Seamless square tube fixed-length processing

Seamless square tube is a term for square and rectangular pipes, which are steel pipes with equal side lengths. It is made by processing steel strips through various techniques, usually by unpacking, flattening, bending, and welding to form round pipes, which are then rolled into square pipes and cut to the required length.

Square pipes are also known as square and rectangular cold-formed hollow steel, abbreviated as square pipes and rectangular pipes, with codes F and J respectively.

1. The allowable deviation of the wall thickness of square pipes: when the wall thickness is not greater than 10mm, it must not exceed ±10% of the nominal wall thickness; when the wall thickness is greater than 10mm, it is ±8% of the wall thickness, excluding the wall thickness at the corners and weld areas.

2. The usual delivery length of square pipes is 4000mm-12000mm, with 6000mm and 12000mm being the most common. Square pipes are allowed to be delivered in short lengths of not less than 2000mm and non-standard products, and can also be delivered in joint pipe form, but the user must cut off the joint pipe when using it. The weight of short lengths and non-standard products must not exceed 5% of the total delivery quantity, and for square pipes with a theoretical weight greater than 20kg/m, it must not exceed 10% of the total delivery quantity.

3. The curvature of square pipes must not exceed 2mm per meter, and the total curvature must not exceed 0.2% of the total length.

Uses of square pipe products: mechanical equipment, solar equipment, steel structures, automotive parts, bridge piles, guardrails, and internal structures of ships.

Latest News